Ralat format e-mel

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Peralatan bilik bersih

Peralatan bilik bersih adalah penting untuk mengekalkan kemandulan dan kebersihan persekitaran terkawal, memastikan kualiti dan kebolehpercayaan produk yang dihasilkan dalam ruang ini. Direka untuk menahan tuntutan standard bilik bersih yang ketat, peralatan bersih merangkumi pelbagai alat dan mesin khusus yang disesuaikan untuk memenuhi keperluan unik pelbagai industri.

Di teras peralatan bersih terletak keupayaannya untuk mencegah pencemaran zarah. Ini dicapai melalui penggunaan penapis udara partikulat kecekapan tinggi (HEPA), yang mengeluarkan 99.97% zarah yang mengukur 0.3 mikrometer atau lebih besar dari udara. Penapis ini digunakan dalam sistem pembersihan udara, memastikan persekitaran bilik bersih tetap bebas dari habuk, kotoran, dan bahan cemar lain yang dapat menjejaskan kualiti produk.

Peralatan bilik bersih juga termasuk pelbagai alat khusus dan stesen kerja yang direka untuk meminimumkan penjanaan zarah. Sebagai contoh, meja kerja yang disahkan bersih dilengkapi dengan permukaan yang lancar, tidak berliang yang menentang pengumpulan habuk dan kotoran. Begitu juga, pakaian dan aksesori yang diluluskan dengan bersih, seperti kot makmal, sarung tangan, dan penutup kasut, dibuat dari bahan-bahan yang bebas dan mudah dibersihkan.

Sebagai tambahan kepada kawalan zarah, peralatan bersih juga mesti menangani isu pencemaran mikrob. Ini dicapai melalui penggunaan lampu UV dan teknik pensterilan lain, yang membunuh atau tidak mengaktifkan mikroorganisma yang mungkin terdapat di persekitaran bilik bersih.

Secara keseluruhannya, peralatan bersih adalah komponen penting dari mana-mana persekitaran terkawal, memastikan kemandulan dan kebersihan yang diperlukan untuk pengeluaran produk yang berkualiti tinggi dan boleh dipercayai. Dengan melabur dalam peralatan bersih berkualiti tinggi, perniagaan dapat memaksimumkan kecekapan operasi mereka, mengurangkan sisa, dan memastikan kepuasan pelanggan mereka.

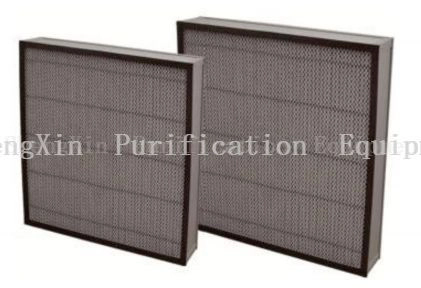

Penapis HEPA

Penapis HEPA Deshengxin dengan cekap menangkap 99.997% bahan pencemar udara sekecil 0.3 mikron, menyediakan penyelesaian udara bersih yang menyeluruh. Penapis kami mengeluarkan pelbagai zarah termasuk bakteria, spora acuan, jelaga, serbuk sari, rambut haiwan, dander, hama debu, zarah asap, dan alergen lain dan zarah-zarah yang merosakkan paru-paru. Menggunakan kertas penapis gentian kaca gred H13-H14, penapis ini menawarkan tahap kecekapan luar biasa H13: 99.97-99.99% @ 0.3um dan H14: 99.99% @ 0.3um (MPPS). Pilihan bingkai yang disesuaikan termasuk kotak profil aluminium, kotak lipatan aluminium, kotak galvanized, dan kotak keluli tahan karat. Setiap penapis dilengkapi dengan perlindungan perlindungan berlian yang dicat dengan serbuk dan dimeteraikan dengan neoprena untuk ketahanan yang dipertingkatkan. Terdapat dalam pelbagai ketebalan profil aluminium antara 46mm hingga 96mm, penapis kami memenuhi keperluan pelanggan tertentu. Sesuai untuk aplikasi di kilang-kilang ultra-bersih, industri semikonduktor, penyelidikan daya atom, bilik bersih, tudung laminar, bangku bersih, dan banyak lagi.

Penapis Kimia FFU

Deshengxin FFU (Unit Penapis Kipas) Penapis Kimia adalah sistem pembersihan udara yang canggih yang direka untuk menghapuskan pelbagai bahan cemar dari udara dalaman. Menggunakan teknologi penapisan canggih, penapis kimia FFU kami mampu menghapuskan asid, alkali, kondensat, dan bahan pencemar yang lain, memastikan persekitaran kerja yang bersih dan sihat. Disesuaikan untuk industri seperti semikonduktor, makmal, dan kemudahan perubatan, penapis kami menawarkan prestasi serba boleh dan pilihan yang disesuaikan untuk memenuhi keperluan rawatan udara tertentu. Dengan pemeriksaan kualiti yang ketat, kestabilan yang boleh dipercayai, dan sokongan pasukan profesional, penapis kimia Deshengxin FFU menyediakan penyelesaian yang sempurna untuk cabaran pencemaran, menyumbang kepada ruang dalaman yang lebih selamat dan bersih.

Penapis Kimia Pleat Mikro Dilipat AMC untuk unit penghawa dingin (MAU)

Deshengxin FFU (Unit Penapis Kipas) Penapis Kimia adalah peranti pemurnian udara canggih yang direka untuk menghapuskan pelbagai bahan cemar dari udara dalaman. Menggunakan teknologi penapisan canggih, penapis ini mampu mengeluarkan asid, alkali, kondensat, dan bahan pencemar yang ditanam lain, memastikan persekitaran kerja yang bersih dan sihat. Ia khusus disesuaikan untuk industri seperti semikonduktor, makmal, dan kemudahan perubatan, yang menawarkan prestasi serba boleh dan pilihan yang disesuaikan untuk memenuhi keperluan rawatan udara tertentu. Penapis kimia Deshengxin FFU menawarkan media penapisan maju yang secara berkesan menangkap zarah -zarah kecil dan bahan pencemar, yang menyediakan udara dalaman yang bersih. Ia juga mempunyai keupayaan penghapusan bau, meneutralkan dan menghapuskan pelbagai bau untuk memastikan persekitaran dalaman yang lebih menyenangkan dan selesa. Dengan kapasiti penjerapan yang tinggi, ia mengurangkan kekerapan penggantian penapis, menurunkan kos dan menjimatkan tenaga manusia. Pemasangan mudah, yang direka untuk kebanyakan peralatan penyaman udara standard, menjadikannya penyelesaian penapisan udara yang mudah dan berkesan. Dengan pemeriksaan dan ujian kualiti yang ketat, penapis kimia Deshengxin FFU menawarkan kestabilan dan ketahanan yang boleh dipercayai untuk operasi jangka panjang. Ia menyediakan pelanggan dengan jaminan penyingkiran pencemaran yang berterusan dan mengurangkan kos penyelenggaraan operasi. Pasukan selepas jualan profesional kami menawarkan perkhidmatan sokongan dan penyelenggaraan teknikal yang tepat pada masanya, memastikan produk kekal dalam keadaan kerja yang optimum dan memberikan jaminan perkhidmatan yang komprehensif kepada pengguna.

Sistem Pengudaraan-Copy

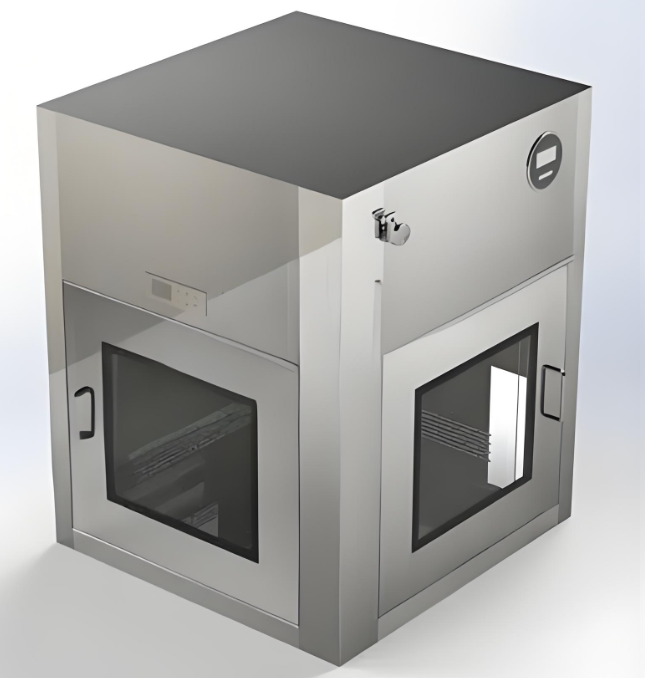

The VHP Pass-Through Box is an advanced sterilization solution designed to maintain sterile environments within pharmaceutical, biotechnology, and healthcare facilities. Utilizing vaporized hydrogen peroxide (VHP) as the sterilant, this box ensures thorough and efficient disinfection of all materials passing through it. Crafted with precision and attention to detail, the VHP Pass-Through Box adheres to the strictest industry standards, featuring a seamless stainless steel construction that is easy to clean and highly resistant to corrosion. The box incorporates cutting-edge technology to guarantee optimal sterilization and decontamination, with automated operation that simplifies the process and ensures consistent, repeatable results. Its flexible configuration allows for adjustable chamber sizes and customizable settings, accommodating a wide range of item sizes and shapes. The intuitive control system provides easy monitoring and control of the sterilization process, with operators able to set parameters, monitor progress, and receive notifications for completion or potential issues. In addition to its efficient sterilization capabilities, the VHP Pass-Through Box is also known for its material compatibility, gentleness on various materials including plastics, metals, and rubber, without damaging their integrity or functionality. The VHP process breaks down into water and oxygen after sterilization, leaving minimal toxic residuals and contributing to sustainable practices by minimizing the need for hazardous waste disposal. Overall, the VHP Pass-Through Box is a robust and reliable solution for industries requiring high-level disinfection and sterilization. Its combination of efficiency, material compatibility, environmental friendliness, automation, flexibility, and safety features make it an ideal choice for maintaining sterile environments in critical facilities. Contact us today to learn more about how our VHP Pass-Through Box can benefit your operation.

VHP melewati kotak-salinan

The Corner Pass-Through Box, a specialized transfer device, features a unique corner design enhancing spatial flexibility. Constructed of two sealed chambers with adapted door mechanisms, it optimizes item transfer in limited spaces, reducing contamination and enhancing efficiency. With excellent sealing, interlock safety features, and intercom communication, it ensures safe, clean, and efficient operations. Designed for ease of cleaning and maintenance, it adapts to diverse environments like electronics factories, pharmaceutical plants, and labs. Its primary purpose is to control contaminant spread, making it ideal for air-purified settings such as LCD factories, hospitals, and food processing industries.

Kotak Pass Dinamik Bersih / GMP Pass-Copy

The DSX Mechanical Interlock Pass Box is a state-of-the-art cleanroom equipment designed to facilitate the secure and contamination-free transfer of materials between different environments. Crafted with precision and durability in mind, this pass box features a robust stainless steel construction and a mechanical interlocking system that ensures both doors cannot be opened simultaneously, thereby maintaining the integrity of the cleanroom environment. With its high filtration efficiency and customizable size options, the DSX Mechanical Interlock Pass Box is an essential tool for industries that require stringent contamination control, such as pharmaceuticals, biotechnology, and electronics manufacturing. Trust Deshengxin for a reliable and efficient cleanroom solution that meets your specific needs.

Interlock Mekanikal Pass-Copy

The Air Shower Pass Box with Automatic Roller Conveyor is an advanced material transfer system designed for use in cleanroom environments. It seamlessly integrates an air shower with an automatic roller conveyor to ensure efficient, contamination-free transfer of materials between different cleanliness zones. The automatic roller conveyor simplifies the loading and unloading process, reducing manual handling and minimizing the risk of cross-contamination. The air shower function, equipped with high-efficiency filters, effectively removes particles and contaminants from the surface of items, maintaining the cleanliness of the cleanroom. Suitable for various industries such as pharmaceuticals, biotechnology, and microelectronics, this innovative pass box offers a customizable design to meet specific requirements and enhance operational efficiency. With its robust construction and user-friendly features, the Air Shower Pass Box with Automatic Roller Conveyor is an essential tool for maintaining hygiene and sterility in high-standard work environments.

Kotak Pas Mandi Udara dengan Copy Conveyor Roller Automatik

This advanced system combines the precision of automatic induction technology with the convenience of a conveyor belt, creating a seamless and efficient process for moving items between different areas while maintaining strict contamination control. The DSX system features an automatic lift door that operates with remarkable accuracy, detecting the presence of items and opening/closing with minimal delay. This ensures a rapid and secure transfer, minimizing downtime and maximizing productivity. The integrated conveyor belt further enhances the system's efficiency, allowing for effortless movement of items from one side to the other, reducing manual handling and eliminating the risk of human error. Crafted from high-quality materials, the DSX Automatic Induction Lift Door Pass Through Box with Conveyor is built to last. Its robust construction and precision engineering ensure that it maintains its performance and reliability over time, even in the most demanding applications. Whether you're in the pharmaceutical, electronics, food processing, or any other industry that requires stringent contamination control, the DSX system offers a tailored solution to meet your unique needs. Its modular design allows for easy integration into existing operations, ensuring a smooth transition and minimal disruption to your workflow. In summary, the DSX Automatic Induction Lift Door Pass Through Box with Conveyor is the ultimate choice for efficient, reliable, and contamination-free material transfer in controlled environments. Experience the future of material handling today with the DSX system.

Box-Copy Pass Door Door Pintu

Introducing the DSX Electronic Interlock Pass Box, a revolutionary solution designed to revolutionize the way materials are securely transferred between cleanrooms. Engineered with precision and innovation, this pass box features an advanced electronic interlock system that guarantees both doors cannot be opened simultaneously, thereby preventing cross-contamination and maintaining the integrity of sensitive environments. Crafted from high-quality stainless steel, the DSX Electronic Interlock Pass Box offers exceptional durability and ease of maintenance. Its sleek and smooth surface facilitates effortless cleaning, ensuring it remains in pristine condition over time. With a range of customizable options available, the DSX Electronic Interlock Pass Box can be tailored to suit specific requirements. From UV sterilization and air ionization to various configurations like window type, desktop type, and floor type, this pass box offers unparalleled flexibility and adaptability. Furthermore, the DSX Electronic Interlock Pass Box boasts an emergency stop button for immediate shutdown in case of emergencies, ensuring operator safety and system reliability. Suitable for a wide range of industries, including pharmaceuticals, biotechnology, semiconductors, food industry, hospitals, data centers, manufacturing plants, and research and development settings, this pass box is a must-have for any organization prioritizing contamination control and secure material transfer. Discover the DSX Electronic Interlock Pass Box today and experience the ultimate in secure, efficient, and reliable material transfer solutions.

Box-Copy Pass Interlock Elektronik

Meet the DSX Advanced Air Shower Pass-Through Box, a top-tier solution for enhancing cleanliness and sterility in controlled environments. Constructed from durable stainless steel, this system employs high-velocity air jets filtered through HEPA/ULPA filters to scrub contaminants from surfaces. Its modular design allows for easy customization, while adjustable airspeed and airflow direction optimize the decontamination process. Additional features like UV sterilization and air ionization can be included for enhanced performance. The DSX Air Shower Pass-Through Box features secure access control, transparent viewing windows for monitoring, and energy-efficient operation. Suitable for industries like pharmaceuticals, biotechnology, semiconductor manufacturing, and more, this system ensures cleanliness and sterility in critical environments.